Options for furniture corners, how to choose

In the process of production and assembly of various furniture, numerous fasteners are used. They have a certain shape, size and other parameters. When creating interior items, a furniture corner is often used, which is a consumable in production, and relates to basic accessories. Using a high-quality corner, a coupler of two flat furniture elements is provided, and they can be made of metal or wood.

Characteristics

The furniture corner has a standard and simple design. It consists of one plate, characterized by a bent shape. The place where there is a fold is a special edge, but the edges of such a plate are called shelves. There can be a different angle between these shelves, since in certain situations products with a blunt, right or acute angle are required.

Furniture corners are created from various materials, but metal structures are considered the most popular, since they differ in long service life, high strength and reliability.

These designs are used for various purposes:

- the creation of a dense internal connection of individual elements, so the products are indispensable in the process of assembling furniture;

- use as a decorative element, for which special decorative corners are used;

- decoration of various shelves or racks, as well as all kinds of boxes;

- a protective corner for furniture provides the creation of optimal conditions for a long service life of interior items.

If a decorative corner is used for furniture, then it can have a variety of unusual shapes, and also certainly painted in different colors, but the most demanded is gilded and silver-plated hardware.

Such products are used for different types of home decoration. They are equipped with upholstered furniture or cabinet and modular designs. The most popular are furniture metal corners formed from steel or aluminum. From above, they are usually coated with zinc, which provides effective protection of the fasteners from the corrosion process. If such a screed is used under normal conditions, when it will not be affected by various negative factors and high humidity, then it will last a long time, preserving its parameters and optimal appearance.

Dimensions and other parameters depend on which material and design it will be used for. This is due to the fact that fasteners are required to cope with a specific load and weight. Surely, symmetrical holes are made for the product on both sides, otherwise it will be skewed, so it will not cope with its purpose.The furniture corner is considered one of the simplest fasteners, so it can be effectively used not only by professionals, but also by beginners in the process of creating different designs.

The main characteristics of the element include:

- universality - there are no special requirements for the place where the corner can join. It is mounted in any corner, and at the same time it is not required to use complex connecting elements or specialized tools. It is only important to choose high-quality self-tapping screws or other screw fasteners that can be equipped with washers and nuts;

- high reliability of the connection - the furniture corner can be used to assemble various designs. It is suitable for fastening shelves or other products on which a variety of heavy objects can be located, while the fasteners will perfectly cope with all the loads. If a reinforced furniture corner is chosen at all, it will not only withstand a substantial mass, but will also have special protective coatings that prevent the corrosion process;

- such components are produced in numerous sizes and shapes, therefore, for each particular mount, the optimal design is selected. It can be used for different materials and products.

Thus, such a screed of various products as a furniture corner is a universal and popular design with many advantages. It can be used for different mounting sites.

Dimensions

This furniture fittings are presented in numerous dimensions. When choosing a specific size, it is taken into account which loads the fasteners will have to cope with, as well as what materials the connected elements are made of.

Depending on the size, the purpose of such a corner is determined. The following types are distinguished:

- products intended for light connections. They have a thickness of 2 mm, and their dimensions do not exceed 40x40x20 cm. This screed is optimal for small shelves or other minor structures on which heavy elements will not be installed;

- products used for angular joints of beams of considerable mass, and it is allowed to use them both in vertical planes and in horizontal ones. Sizes can vary from 40x40x60 to 100x100x100 mm;

- mounting corners that are reformed. They are equipped with special additional holes designed to use a durable hex bolt. Such products are used for fastening really heavy structures;

- reinforced corners intended for use in the construction industry by professionals. The sizes of such products can vary significantly, and often for the construction of various specific buildings you need to buy such corners to order;

- locknut elements that are reinforced and perforated, and their sizes can be different.

Thus, the corners are presented in different sizes, and their choice depends on the scope.

It is not recommended to use reinforced structures to fix a regular shelf, since the cost of their purchase will be high, and at the same time they will not have advantages compared to conventional fasteners.

Materials of manufacture

These furniture covers can be made of various materials. The most popular are:

- metal corner for furniture - is a stamped product of considerable massiveness. It is equipped with stiffening ribs. There is a hole at one end, and a groove at the other. The coupling is used for fastening and screws. Also, metal products can be presented in the form of a single strip, which is bent at an angle of 90 degrees. Fastening is carried out with self-tapping screws, so it is considered easy to use.

- plastic corners - usually have small dimensions, and standard self-tapping screws are used for their fastening. The plastic corner can only be used to fix small and light structures.

All products fastened with corners can become loose over time, and these fasteners are considered not too attractive, since they often protrude and spoil the appearance of the rooms.

Plastic

Plastic Metal

MetalFields of application

Such furniture plastic or metal corners are used for different purposes. Their main purpose is the assembly of various modular or cabinet interior items made of wood, particleboard, metal or other materials.

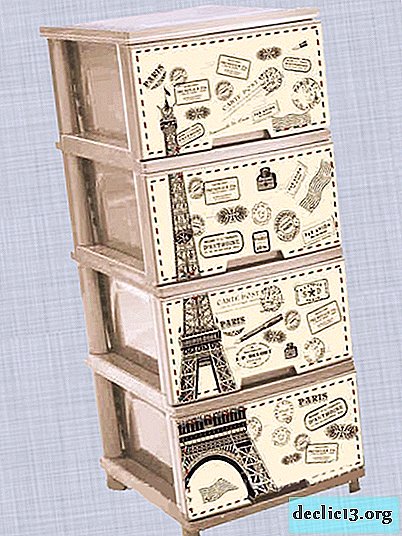

Due to the correct use of the corners, a reliable connection of two parts is ensured. It is optimal to use them for the assembly of different cabinets or cabinets, drawers or other similar structures.Often corners are used to fix the shelves or just a reliable connection of two separate structures.

What to look for

The choice of corners should be competent, therefore, certain criteria are taken into account in the process of their selection:

- fastener manufacturing material;

- product size

- purpose, since certain designs can be intended exclusively for working with wood, while others are universal;

- the weight that the fasteners must withstand, as they must cope with their main task;

- Operating conditions.

Thus, furniture corners are quite popular mounting structures. They are presented in different forms, and also differ in a variety of factors. It is important to choose the fasteners correctly so that they can withstand a certain weight and have a long service life, a strong screed is provided.